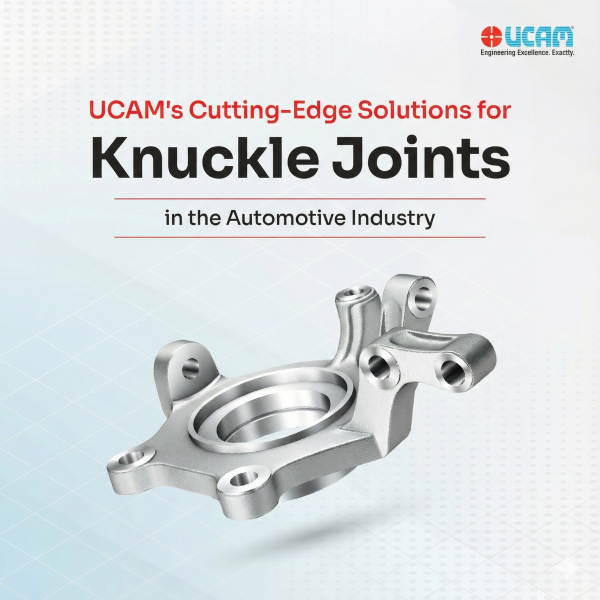

Knuckle joints are vital components in the automotive industry, especially within suspension and steering systems. They serve as connectors between the suspension control arms and the wheel hub, playing a crucial role in transferring forces between the wheels and the vehicle’s chassis.

However, the complex profile of knuckle joints presents significant manufacturing challenges. Machining them requires precision across multiple surfaces.

UCAM’s USSR 200Q TN 4RU CNC Rotary Table effectively addresses these challenges, providing superior accuracy and flexibility for knuckle joint manufacturing. Here’s how it stands out:

- High Indexing Accuracy: Featuring a rotary axis accuracy of ±15 arc seconds and a tilting axis accuracy of ±30 arc seconds, this rotary table ensures exceptional positional precision, critical for the intricate machining of knuckle joints.

- High Repeatability: With a repeatability of 4″, it offers consistent performance, guaranteeing that each knuckle joint is machined to exact specifications.

- Wide Tilting Range: The tilting capability ranges from -30° to +110°, enabling complete machining of the knuckle joint in a single setup, thus reducing production time and improving efficiency.

Looking for solutions to transform your machining? Contact us!