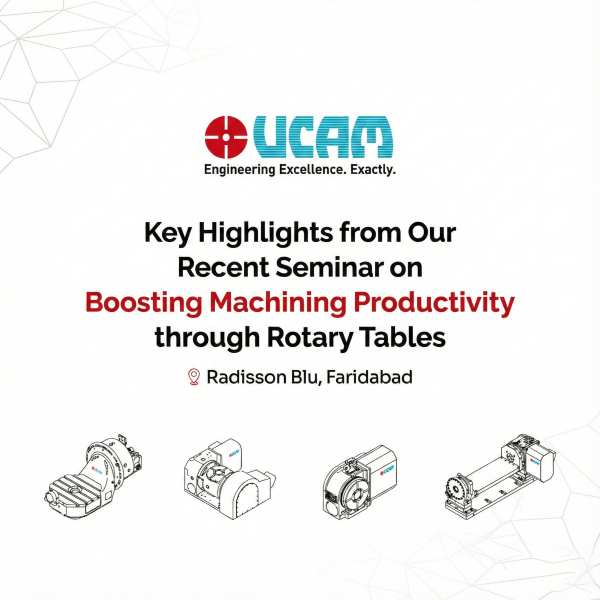

Today’s CNC machining challenges demand more than just precision — they call for smarter, more efficient setups that can handle complex geometries with ease. That’s why 5-axis machining has become a standard for manufacturers looking to increase flexibility, reduce cycle times, and maintain quality.

However, the true performance of a 5-axis setup depends heavily on the Rotary Table.

At UCAM, we design and manufacture high-performance tilting rotary tables that enhance machine capabilities across various applications. Whether you’re upgrading a compact 3-axis VMC or working with large, high-inertia components, our 5th-axis solutions are built to improve accuracy, productivity, and reliability.

Why the Right Rotary Table Matters

5-axis machining offers a major leap in efficiency by enabling movement along three linear and two rotary axes. This allows complex parts to be machined in a single setup, delivering:

- Reduced fixture changes

- Increased tool life

- Improved part accuracy

- Shorter cycle times

However, to fully understand these benefits, your system needs a precision Rotary Table that provides exceptional positioning, high rigidity, and reliable tilt and indexing, especially under demanding loads.

UCAM’s 5th Axis Rotary Table portfolio is engineered with these exact needs in mind.

Q Series Tilting Rotary Table: Compact Power for VMC Upgrades

Models: USSR 150q TN, USSR 200q TN, ULSR 200q TN, USSR 250q TN.

The Q Series Tilting Rotary Table is UCAM’s solution for upgrading 3-axis Vertical Machining Centers (VMCs) into full 5-axis platforms — without compromising on workspace, performance, or integration.

Key Features:

- Compact & Lightweight Design

Engineered to integrate into smaller VMCs while maximizing available workspace. - Pneumatic or Hydraulic Clamping

Gives manufacturers the flexibility to select a clamping mechanism suited to their process needs. - Rotary Union-Ready

A 4-line rotary union can be fitted any time after installation, enabling features like through-spindle coolant or air. - Quick & Easy Installation

User-friendly design ensures fast integration with servo motors and electrical connections. - Robust Tilting Axis

Stronger tilt mechanism supports heavier parts and helps maintain high positional accuracy. - IP65 Rated

Built to withstand coolant-heavy environments and continuous machining conditions.

The Q Series also supports a wide range of accessories, including tailstocks (manual, pneumatic, or hydraulic), rotary cylinders, chucks, and vices — making it a turnkey solution for 5-axis conversion.

Best suited for: Job shops and OEMs looking to enhance productivity on small to mid-sized VMCs.

H Series & Large Bore Rotary Tables: Built for Heavy-Duty Machining

Models: URH 320 TN, ULBR 320 TN, ULBR 400 TN

The H Series and Large Bore Tilting Rotary Tables are engineered to handle high cutting forces, heavy components, and continuous duty cycles. Ideal for machining large steel and cast iron parts such as rock drill bits and structural components.

Key Features:

- High-Rigidity Cast Iron Structure

Absorbs vibration and offers exceptional stability during aggressive machining. - Dual Axis Clamping

Clamping mechanisms on both the tilt and support axes improve holding torque and reduce deflection. - Large Through-Bore in Rotary Axis

Supports oversized and elongated parts for improved fixturing and overall rigidity. - High Gear Ratio & Output Torque

Larger module gears deliver the torque needed for high-inertia components and robust workholding.

These models offer superior torque handling and repeatability, especially under continuous load — a must-have for high-volume, heavy material cutting.

Best suited for: Heavy engineering and industrial part machining where high torque and rigid 5th-axis setups are essential.

Deep Tilting Rotary Tables: For Large Workpieces and Extended Swing

Models: URH 320 DT, URH 400 DT

The Deep Tilting Rotary Table series is designed for operations that require a larger swing diameter and deep component access, making them ideal for aerospace, energy, and large-format precision manufacturing.

Key Features:

- Large Work Envelope

Extended swing capacity allows room for bulky components and fixtures. - Table Top Alignment with Tilt Axis

Balances load on the tilt axis to reduce stress and ensure better accuracy during rotation. - Dual Axis Clamping for Rigidity

Maintains stability and precision when tilting or holding large masses under high cutting loads. - High Allowable Work Inertia

Carries heavy fixtures and components without losing speed or accuracy. - High Gear Ratio for Driving Torque

Supports deep cuts and heavy-duty cycles without mechanical strain.

This series is built for demanding operations where part weight, size, and machining complexity make standard rotary tables insufficient.

Best suited for: Large component machining, especially where deep tilting and high moment of inertia handling are required.

UCAM Advantage: Engineering Support from Start to Finish

UCAM’s rotary tables are not just standalone components — they are part of a larger ecosystem of precision, support, and long-term reliability. Whether it’s selecting the right model, integrating accessories, or optimizing post-installation performance, UCAM provides:

- Application-driven consultation

- Tooled-up solution design

- On-site support and service network

- Consistent availability of spares and technical guidance

We collaborate closely with machine tool builders and end-users alike to ensure every rotary table operates at peak performance throughout its lifecycle.

Unlock True 5-Axis Potential with UCAM

Choosing the right 5th-axis rotary table is the difference between a capable machine and a truly productive one. With UCAM’s range of tilting rotary tables — from compact VMC-compatible models to torque-heavy deep tilt and large bore systems — manufacturers gain the flexibility, accuracy, and reliability needed to stay ahead in a competitive landscape.

Whether you’re making your first move into 5-axis machining or upgrading for higher loads and tighter tolerances, UCAM is the partner that delivers performance you can trust.

Ready to optimize your machining with UCAM’s 5th axis solutions? Contact us today.