Appended below are a few of our selected products with their layouts, specifications and 3D models for download. That aside, we also have brochures and catalogues you can take a look at for a deeper insight and understanding.

The URX Series

![]() Download

Download

UCAM’s most compact and best-selling range of rotary tables. Compatible with almost any machining center. UCAM’s new CNC URX rotary tables offer significantly higher speeds and higher clamping torque, simplifying the machining of complex components such as turbine blades, when used in sync with machine axes. A dual gear mechanism allows for precise transmission of torque from the motor to the rotary table.

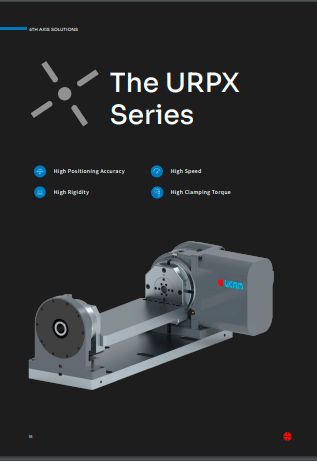

The URPX Series

![]() Download

Download

UCAM’s modular masterpiece, this precision production system allows for unparalleled customizability to match demanding manufacturing needs. The batch production method is crucial in subtractive manufacturing. Parts that require a high degree of quality control, precision, and routine monitoring during production, need this process. That’s the reason a rotary production system is a must in every machining facility. UCAM rotary production system(URPX) enables you to save time, reduce set-ups and take advantage of the batch production methodology

The URH (MULTISPINDLE)

![]() Download

Download

UCAM Multi-spindle rotary tables feature more than one spindle driven by a single motor. Such multispindle rotary tables give you the breathtaking ability to mill two or more components in the same machine, simultaneously, with the same precision. The only effort required? Imagining the immense savings in loading-unloading, processing and programming times. Even single spindle machining centres benefit from our multiple-spindle tables, with drastic reductions in loading-unloading and tool change times.

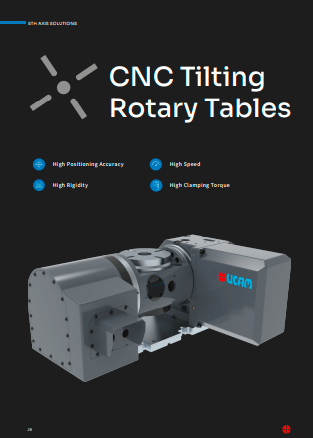

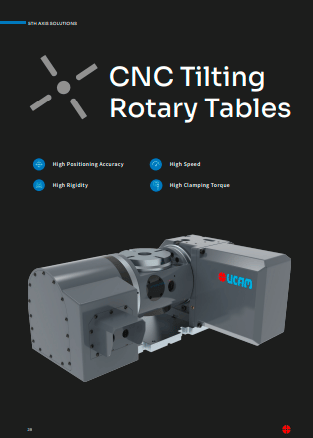

CNC Tilting Rotary Tables

![]() Download

Download

Turns your standard 3-axis VMC CNC into a 5-axis. UCAM’s CNC Tilting Rotary Tables grants two additional axes of rotation (the 4th and 5th axes) to the XYZ axes in basic CNC units. This allows the VMC to access faces of components not available to standard CNCs. Such tilting tables easily interpolate with machine axes, allowing you to create complex profiles such as impellers.

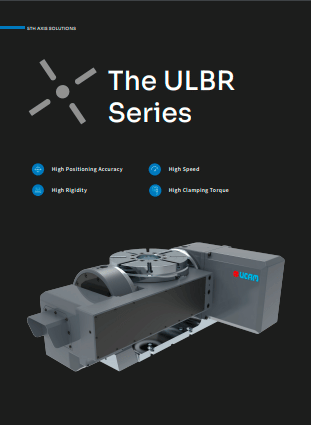

The ULBR Series

![]() Download

Download

When precision has to scale with size. This ULBR rotary solution allows for the milling of large, heavy complex components at one station, doing away with strenuous repetitive loading and unloading operations across the factory floor.

CNC Deep Tilting Rotary Table

![]() Download

Download

When precision has to scale with size. This rotary solution allows for the milling of large, heavy complex components at one station with High Positioning Accuracy and High speed.

CNC Direct Drive Tilting Table

![]() Download

Download

UCAM’s Direct Drive Tilting Rotary tables are powered directly by high torque motors, eliminating the worm gear so as to ensure zero backlash. Ideal for applications requiring highacceleration/ deceleration.

Value Added Accessories

![]() Download

Download

Tailstocks are used in conjunction with a CNC rotary table on a milling machine when the components are lengthy.A tailstock enables a CNC machine to precisely and safely process shaft-type work pieces. The tailstock is typically used to support the components via the use of a dead centre or Live centre. The tailstock can be moved along the bed to accommodate the component of varying lengths.

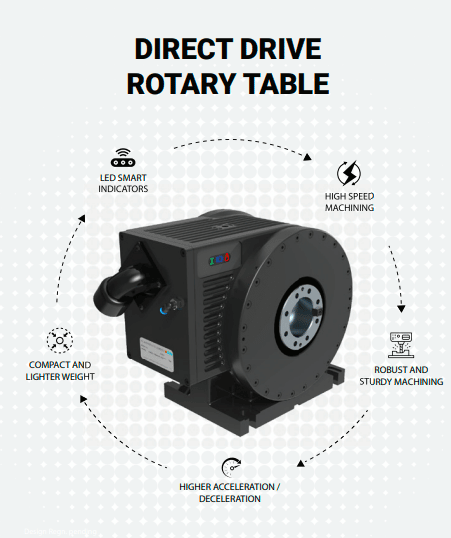

Black DDRT catalogue

![]() Download

Download

This DDR allows heavier machining due to high continues torque.Motor tech plus has no chilling system makes the unit exceptionally reliable and hence superior MTBF,Small Footprint saving precious space on Machine Bed.Clever design allows Efficient Heat Dissipation, achieving higher torque.