Indexing

Technology.

Such invisible and innovative technologies in our products lead to a relationship built with our customers.

Such invisible and innovative technologies in our products lead to a relationship built with our customers.

It’s constant improvement that keeps our tables rolling out ever greater accuracy and pace across the factory floor. Our collaboration with a gamut of respected institutions goes a long way in aiding this process. But key components and technologies, arrived at through decades of refinement, like those presented below, are integral in giving our tables the unmistakable UCAM touch.

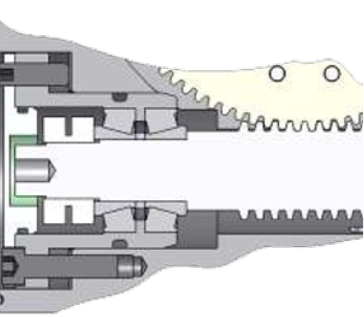

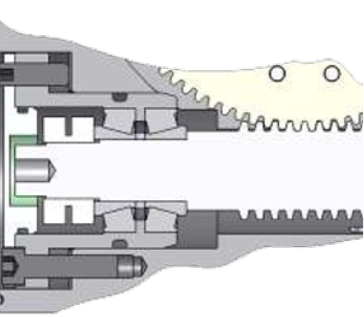

A renowned German institution has validated the innovative design of the twin lead worm gear. This drive technology is employed in all 4th and 5th axis Rotary tables.

Backlash is simply adjusted by moving the worm shaft axially without affecting the worm and worm wheel's critical centre distance and axial alignment.

Direct Drive Rotary Tables are powered by Nimble Electric (a division of UCAM Pvt. Ltd.) torque motors where high-speed and high-torque torque motors are used. These rotary tables have low backlash, high stiffness, quick reaction, and less wear and tear than traditional rotary tables.

Large diameter internal/external gear is powered by two precision pinions, which are operated by either a single motor or two motors, allowing for perfect indexing of greater weights. Because double pinion gears are less prone to wear and tear, backlash issues are minimal. This driving technique is commonly employed in big Rotary Tables with high peripheral velocities.

The Cross Roller bearing is a high-precision bearing that can support loads in every direction. In general, it offers high load capacities and offers a small coefficient of friction for high-speed rotation.

The pressurised fluid film in this bearing prevents direct metal-to-metal contact during rotation. This internal lubrication drastically cuts down wear and tear on the insides. The pay off with this bearing technology is observed in its long operating life in medium and large-size rotary tables that see heavy duty application.

.png)