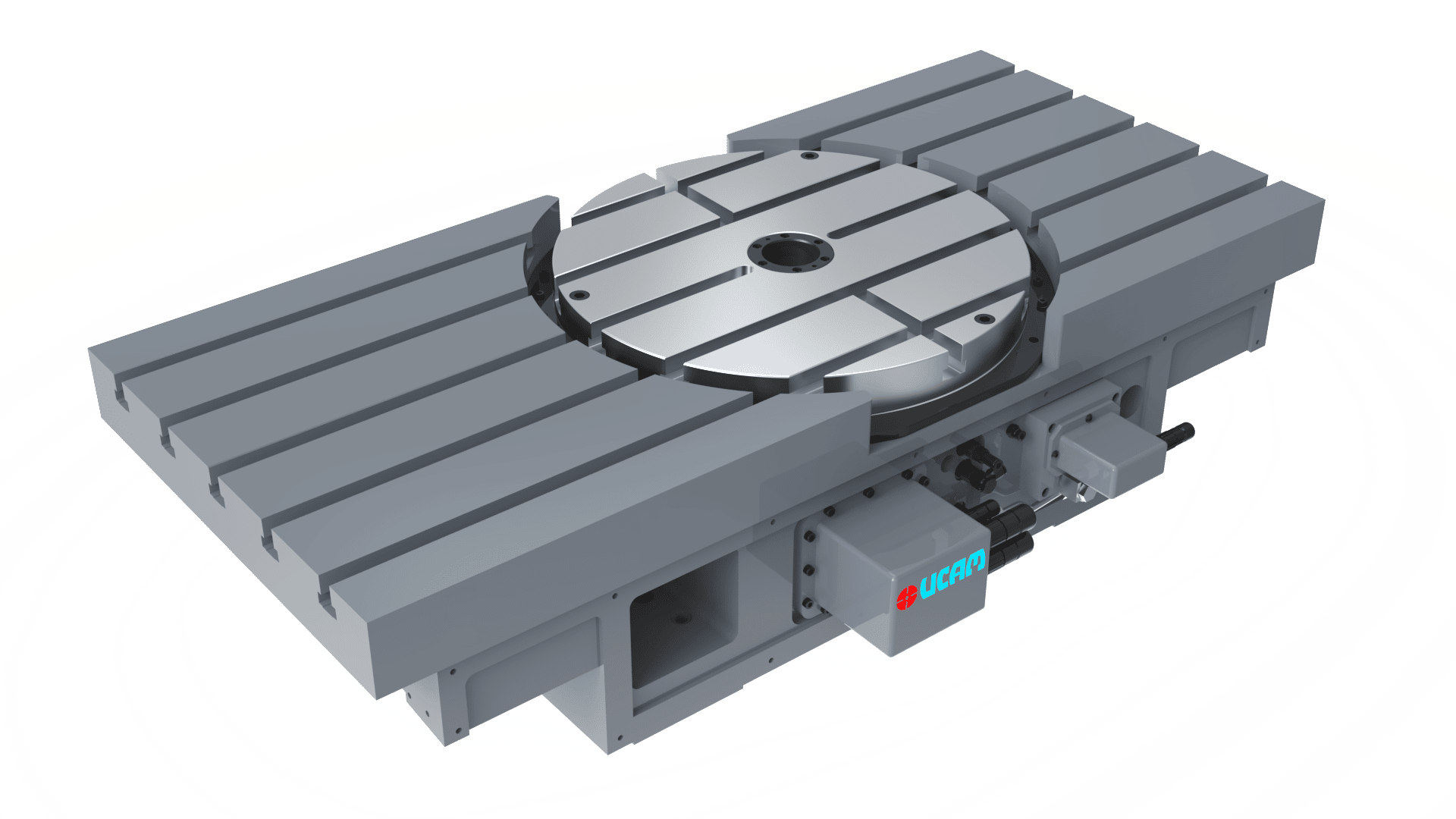

Product Features

Spec Sheet

Note: We give special modifications according to the customer needs.

Product Video

Product video not found

Downloads

Note: We give special modifications according to the customer needs.